CuriousJake

New member

Hi all;

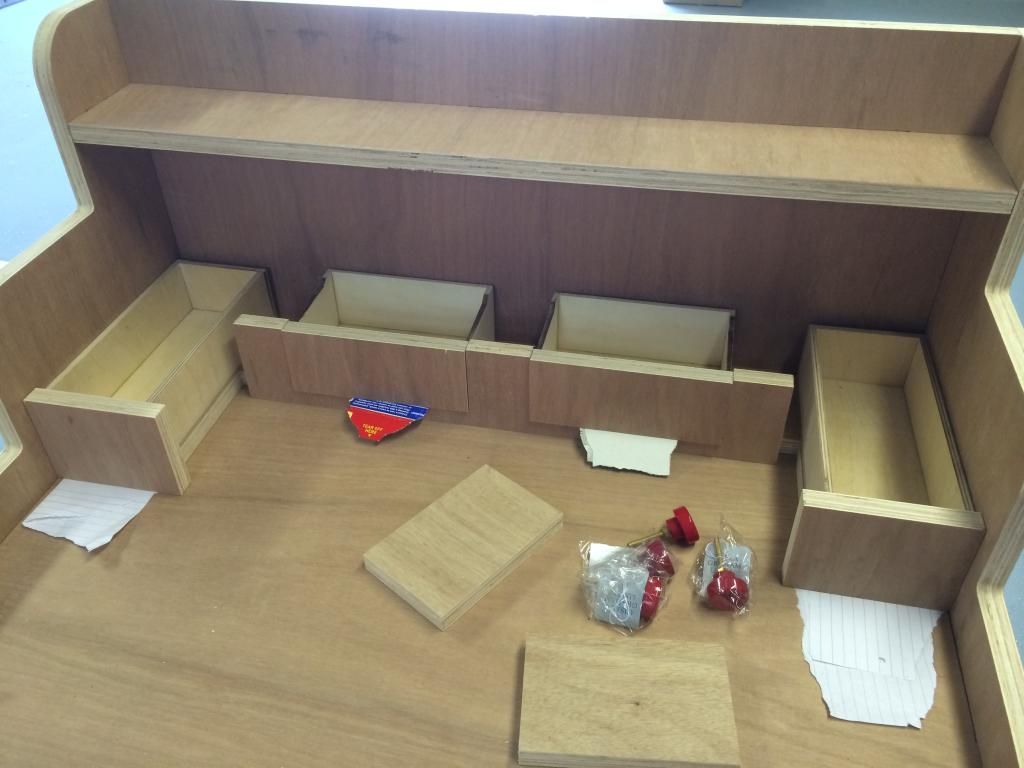

I want to build a PC desk with shelves to the side/top, and have done a design in Google SketchUp. Dimensions 70" high, 42" wide and 26" deep (20" deep for the shelves).

Hopefully the joints I've gone for are a good idea too, Mortise & Tenon and going to use small angle brackets with screws to hold it together.

I intend to use plywood, and my question is what thickness to go with? I originally thought 18mm, but a friend has suggested that'll be overkill (and heavy), so know I'm thinking of 12mm and using a couple of wooden batons under the main desk to prevent it flexing.

Also - what do you think of my design? Our flat is terrible for storage, so some big deep shelves should give me ample space for piling up the awkward items!

Has anyone got any advice for me?

Many thanks in advance for any help!

I want to build a PC desk with shelves to the side/top, and have done a design in Google SketchUp. Dimensions 70" high, 42" wide and 26" deep (20" deep for the shelves).

Hopefully the joints I've gone for are a good idea too, Mortise & Tenon and going to use small angle brackets with screws to hold it together.

I intend to use plywood, and my question is what thickness to go with? I originally thought 18mm, but a friend has suggested that'll be overkill (and heavy), so know I'm thinking of 12mm and using a couple of wooden batons under the main desk to prevent it flexing.

Also - what do you think of my design? Our flat is terrible for storage, so some big deep shelves should give me ample space for piling up the awkward items!

Has anyone got any advice for me?

Many thanks in advance for any help!