Jacob":3cyvabin said:

That's a very elaborate and inconvenient way of doing a simple little job! I think you just need a bit more practice with planing against stops. What if you had a few dozen to do, with different lengths?

I had, as I said, tried planing against my bench stop, and, as I said, found that the small, light, hard piece of old oak skidded round, making it hard to control. I did have quite a few to do, all about the same length, as they were runners, sides and ends for small drawers.

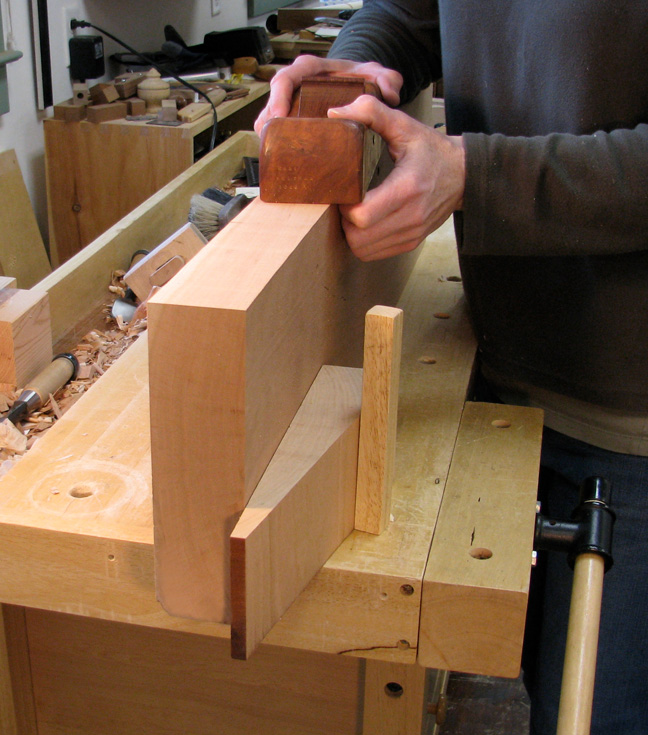

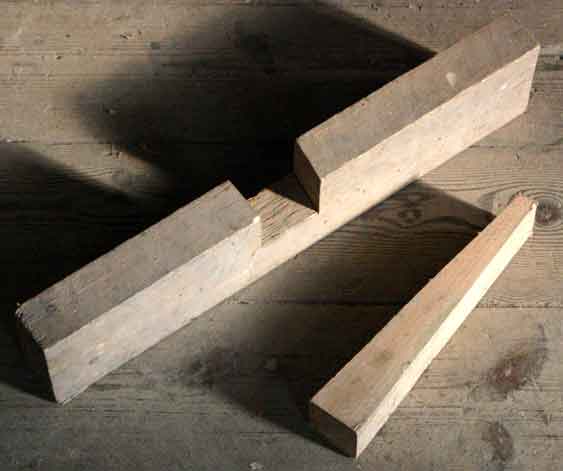

So it was worth my while to find a method which suited me, at my skill level, for these fiddly pieces which I needed to reduce from roughly 1/2" to 3/8" thick. My bench has a stop, a Record 52½ and holes for holdfasts, but no tail vice. This method gave me sufficient end pressure while leaving the work clear.

I don't work in a production environment, so sometimes I will take time to experiment with different methods of doing something - gaining experience so that I can make comparisons. I found this method simple and convenient. It needed a piece of scrap from behind the bench, cut to size on the bandsaw - time taken, about thirty seconds - and a wedge from the box of wedges.