Bkn

Established Member

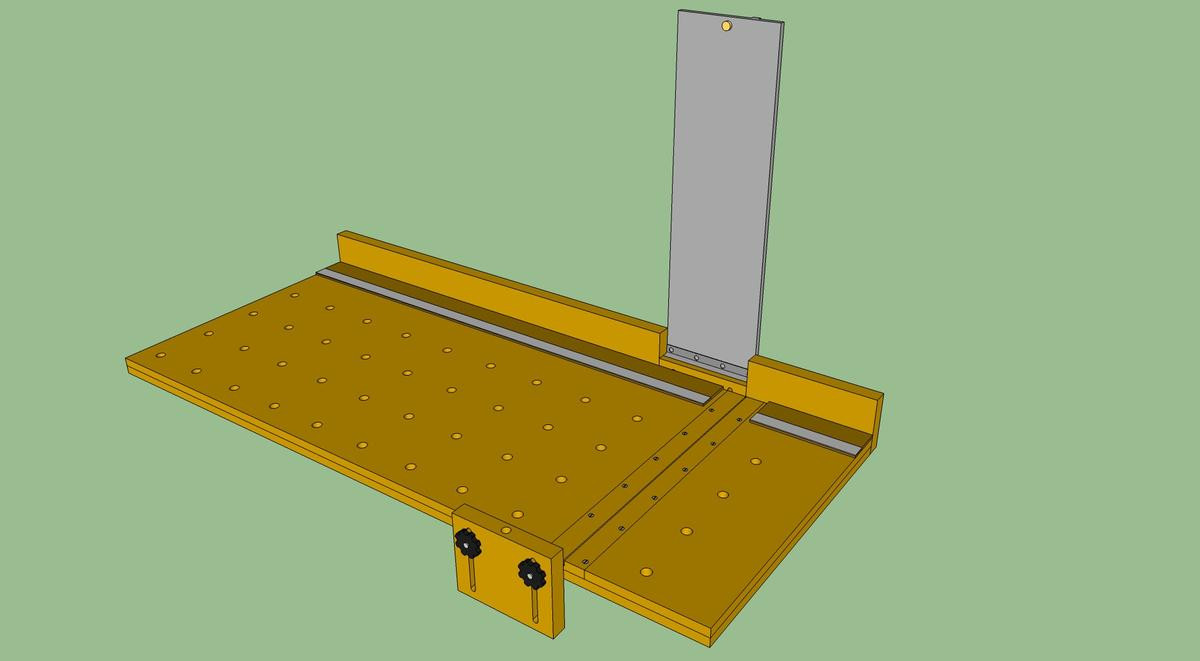

Due to space limitations I can't really fit a table saw anywhere but I'd still like to be able to accurately cut decent sized bits of sheet material and small bits of timber. It'd hopefully be used in place of both a table saw and mitre saw.

I've come up with a little work station type thing and was wondering if there are any glaring flaws with it that I'll need to make modifications to.

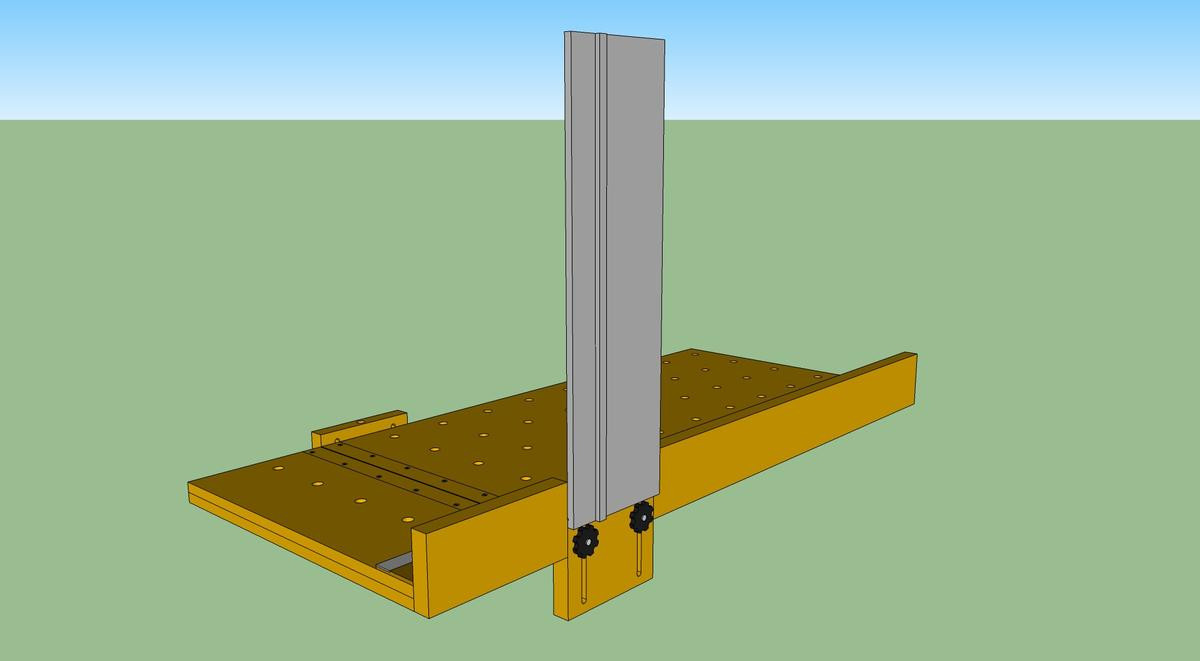

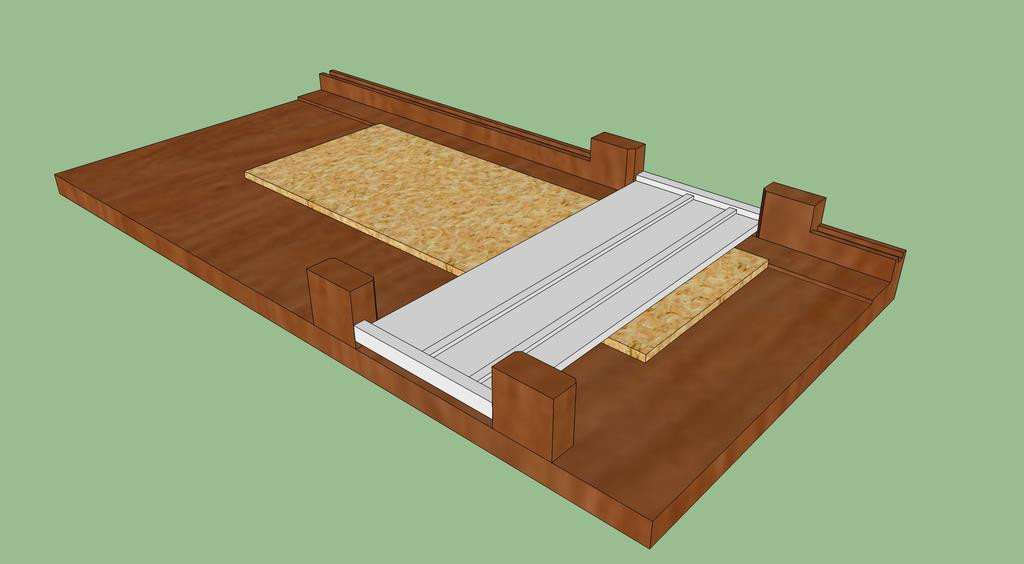

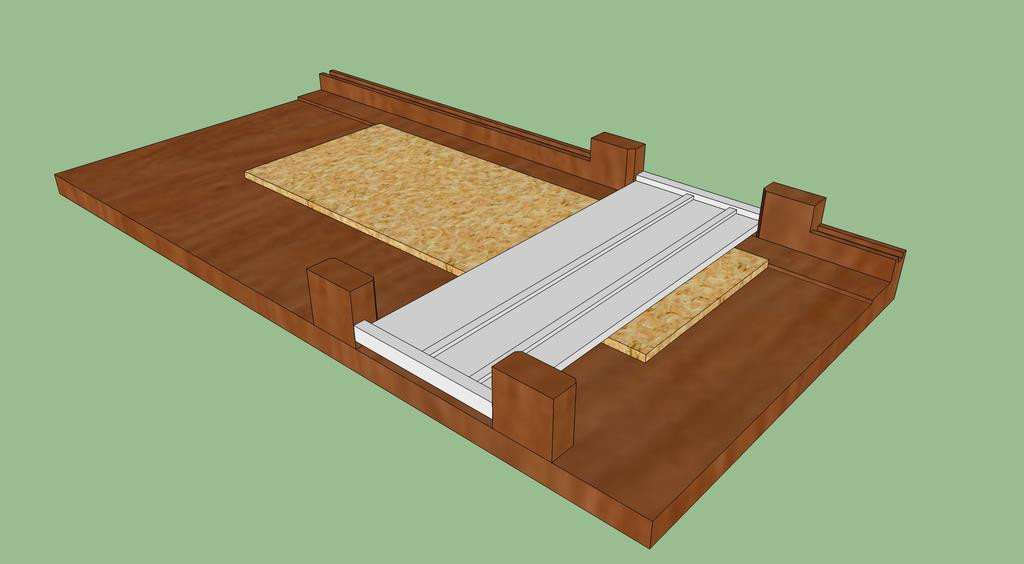

The saw would obviously run on the rail (it'd be nice if I could come up with a sliding hinge mechanism for the back that'd work with different material thickness's).

Maybe put some T-track along the back rail so I could attach stops etc.

I'm going to redesign the whole thing but I just wanted to get a quick idea down to work from. There's a big limitation in that it can't really do cuts at an angle and I'd like to try and figure out a way to rectify this (somehow get rid of the front guides maybe).

I've come up with a little work station type thing and was wondering if there are any glaring flaws with it that I'll need to make modifications to.

The saw would obviously run on the rail (it'd be nice if I could come up with a sliding hinge mechanism for the back that'd work with different material thickness's).

Maybe put some T-track along the back rail so I could attach stops etc.

I'm going to redesign the whole thing but I just wanted to get a quick idea down to work from. There's a big limitation in that it can't really do cuts at an angle and I'd like to try and figure out a way to rectify this (somehow get rid of the front guides maybe).