vincent

Member

Hi Everyone,

I've got a problem with the raising and lowering of the blade.

It has never been easy, small hanwheel and pretty tight,

but lately it becamed a real pain to raise the blade up and down.

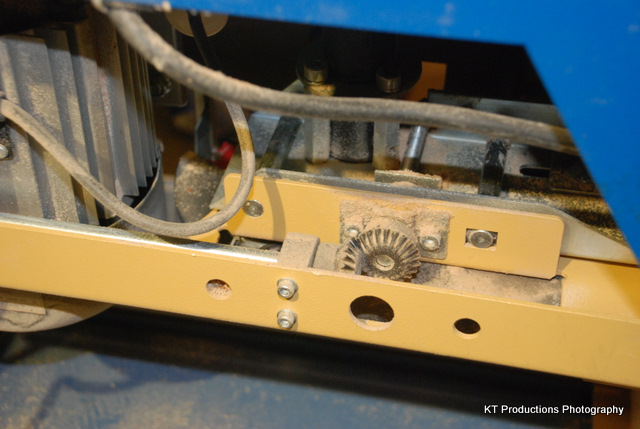

Looking from under, I can't see anything wrong; what I can't see is what happen after the "jointing elbow"

It conect to a sort of shaft that seems to be responsible for the raising up and down of the blade.

Any idea what I can do, just using a lubricant does not seems a good idea with all the saw dust.

Thanks for your answer and apology for my english

vincent

I've got a problem with the raising and lowering of the blade.

It has never been easy, small hanwheel and pretty tight,

but lately it becamed a real pain to raise the blade up and down.

Looking from under, I can't see anything wrong; what I can't see is what happen after the "jointing elbow"

It conect to a sort of shaft that seems to be responsible for the raising up and down of the blade.

Any idea what I can do, just using a lubricant does not seems a good idea with all the saw dust.

Thanks for your answer and apology for my english

vincent